Researchers at ETH Zurich announced a study capable of changing the physical limit of what we understand as a pixel. A new technology Nano-OLED manages to reduce the size of light-emitting diodes to the 100 nanometerssomething close to 50 times smaller than the current standard of the industry.

The achievement increases pixel density to unprecedented levels and opens the door to applications ranging from ultra-compact screens to new optical systems that manipulate light precisely.

What makes Nano-OLED so different

The research published in the renowned scientific journal Nature Photonics presents a manufacturing method that miniaturizes OLEDs in a single step.

The process uses ultra-thin membranes of Silicon Nitriderigid and stable ceramic material that functions as an exceptionally thin lithographic mask.

It is precisely this characteristic that allows the creation of patterns with spacings smaller than the wavelength of the emitted light itself.

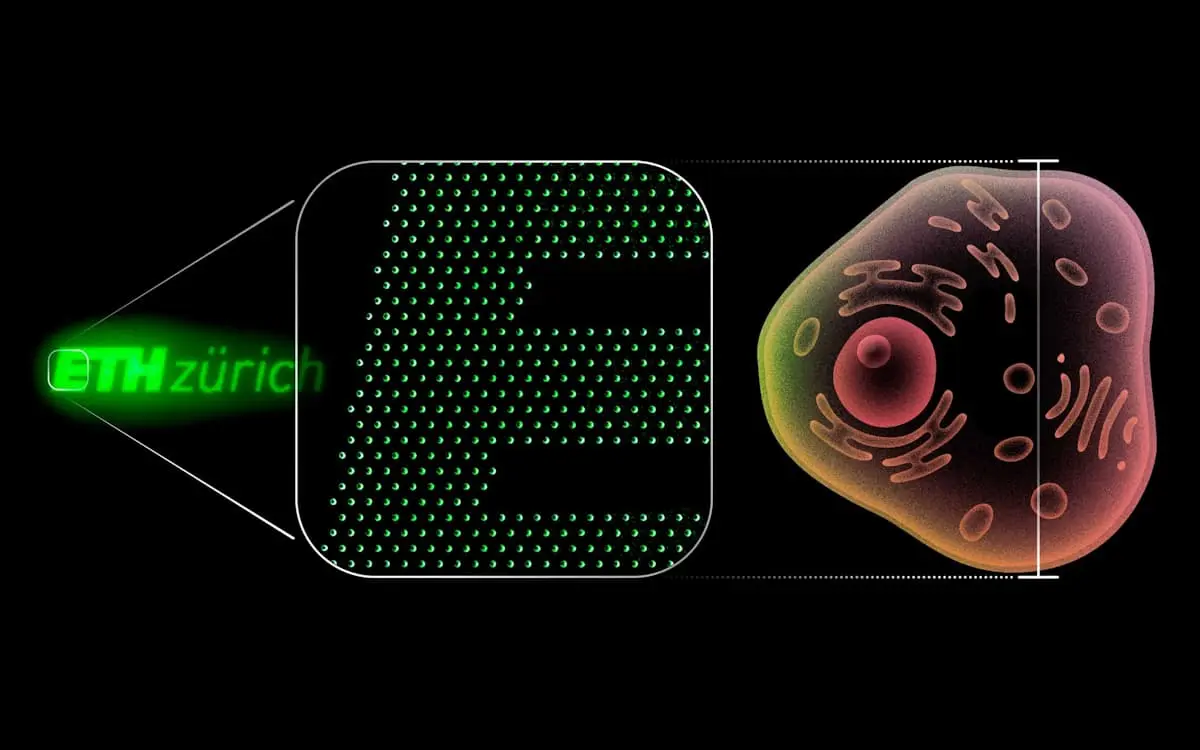

The experiments showed pixels with 100 to 200 nanometersdensity equivalent to 100.000 ppi. For comparison purposes, the current premium standard for XR headsets is between 3,000 and 5,000 ppi.

The new scale is so extreme that scientists were able to print the ETH logo on an area the size of a human cellmade up of 2,800 nanopixels.

Miniaturization reaches a limit where neighboring lights interact with each other, creating complex optical patterns and allowing you to control direction and polarization precisely without a lens

How the manufacturing process works

The method is based on a set of coordinated steps:

1. Very thin membranes

Called nanostencils, they are 30 to 50 nm thick and remain stable without deforming. This rigidity is mandatory to keep the openings aligned on the surface where the OLED will be deposited.

2. Nanoscale evaporation and recording

The microscopic openings function as molds that define the size of the pixels. As the process is resist-free, there is no direct exposure of organic materials to aggressive solvents, preserving their efficiency.

3. Direct integration with traditional processes

The researchers emphasize that the technique can be inserted into the normal lithography pipeline used in semiconductors, something rare in emerging technologies.

The result is the possibility of manufacturing matrices with more than 1 million nanopixels with external quantum efficiency greater than 13%, a value close to that of larger-scale conventional OLEDs.

The most likely initial impact appears in very high density screensespecially for smart glasses, XR headsets and digital microscopes. The proximity between eye and display requires almost invisible pixels, and Nano-OLED creates this scenario.

Another field that should benefit is optical sensingas the reduced size of the pixels makes it possible to record subtle variations in light emitted by individual tissues, cells or neurons.

There is potential for biomedical research equipment and ultra-specific diagnostic platforms.

Technology also advances in the territory of electroluminescent metasurfacesa type of optical architecture that rearranges light waves based on the position of nanopixels. This creates effects like:

- Lensless beam steering: The array can throw light at specific angles, something key for mini lasers and short-distance optical communication.

- Controlled polarization: the alignment of the emitters allows polarized light to be produced directly at the source. Today this is done with filters that waste part of the luminosity.

- Calculated diffraction: Positioning emitters below the diffraction limit causes waves to reinforce or cancel each other out, a form of light engineering previously restricted to radio and radar antennas.

Open path for holograms, lasers and optical communication

The team already speculates that controlling the pixels individually would transform Nano-OLED matrices into structures equivalent to phased array antennas, known for guiding electromagnetic beams with millimeter precision.

In the field of visible light, this means more defined holograms and very high-speed data transmissions.

Researchers envision three-dimensional meta-pixels capable of projecting images around the viewer, creating volumetric experiences without relying on additional screens or glasses.

Also read:

What to expect from technology in the coming years

Although the study presents solid results, it is now necessary master individual control of each nanopixel. Only in this way will it be possible to explore the full potential of light manipulation at the submicron level.

Another challenge involves bringing the process closer to an industrial scale, as creating such thin masks still requires high-precision equipment. Even so, the fact that the method is compatible with industrial processes is an indicator of feasibility.

Recent advances in Nano-OLED draw a transition to devices capable of manipulating light as waves and not just as points of light. It’s a paradigm similar to the leap from 2D to 3D in computer graphics: it changes the type of technology that becomes possible.

If miniaturization continues at the pace presented by the ETH Zurich team, we will see a scenario in which screens, sensors and optical systems begin to operate on such small scales that the distinction between hardware and physical phenomena becomes increasingly blurred. And this is where the next generation of visual interfaces may emerge.

Source: ETH Zurich and Nature

Join the Adrenaline offer group

Check out the main offers on hardware, components and other electronics that we found online. Video card, motherboard, RAM memory and everything you need to build your PC. By joining our group, you receive daily promotions and have early access to discount coupons.

Join the group and take advantage of promotions

Source: https://www.adrenaline.com.br/tech/tecnologia-nano-oled-telas-novidade/